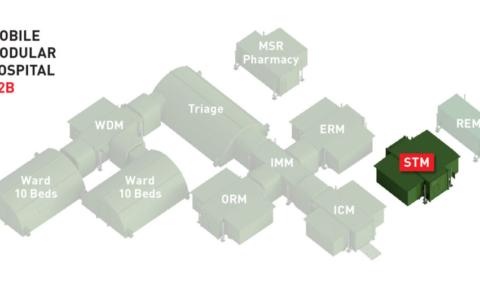

STM – Sterilization Module

Description

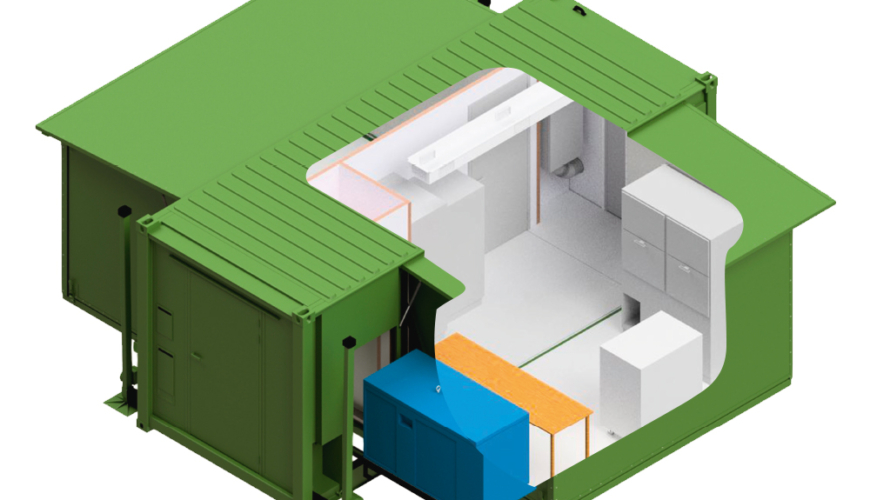

STM is a sterilisation unit, designed to support a full hospital with sterilization services for surgical and other instruments.

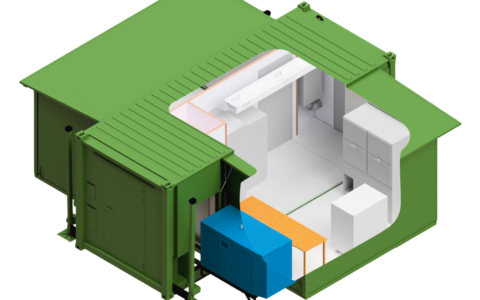

STM can be made autonomous with its own power generators, and steam generators. The module includes washer-disinfectors, steam autoclaves, instrument storage, transportation carts, and accompanying workstations.

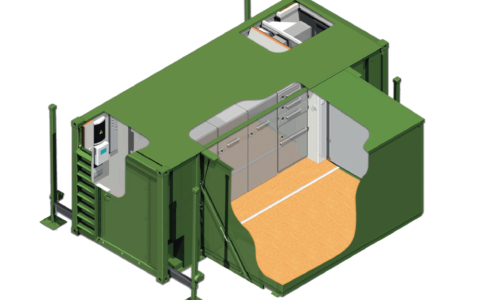

STM is divided into clean and soiled areas. The soiled area is for initial cleaning, soaking, washing, and sealing of the instruments.

The clean area is for instrument collection from the autoclave, and clean instrument storage. Instruments are stored in clean trolleys, ready for distribution.

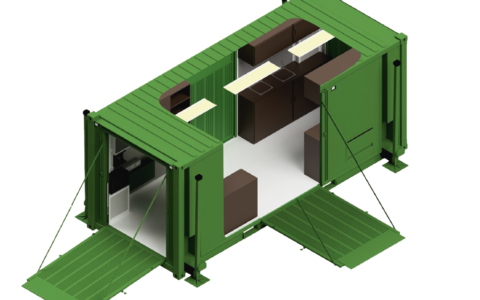

The unit has built-in levelling legs, which makes loading and unloading a unit from a truck or barrow possible without extra cranes or lifting units. With ISO 1CC Certification, all MMH modules are designed for easy transportation via sea, land, and air.

Specification

| Gross weight: | 12 000 kg |

| Load capacity: | 6 000 kg |

| Dimensions according to ISO668 | 1CC (20ft) |

| Total length: | 6058 mm |

| Height: | 2591 mm |

| Width in transport: | 2438 mm |

| Width when opened: | 6795 mm |

| Insulation: | 50 mm XPS |

| Floor area when expanded: | ~34 m2 |

| Standards: | ISO 1161: 2016, ISO 1496-1-5: 2013, CSC Certificated |

| Operating temperature: | from -40°C to +50°C |

| Deployment and repack time: | 20 minutes |

| Equipment: | 10 kW generator, Sterilisation capacity 4STU, Workstation with laptop, Workflow divided between clean and soiled areas, 2 steam sterilisers, 2 washer-disinfectors, Ultrasound soaking bath, Air dehumidifier, Instrument sealer, Distribution cabinets, Clean instrument holding, Water treatment for steriliser Air conditioning, Electrical and diesel heating |

Contact us

You can write to us here

If you have questions and requests that require detailed consideration and a detailed answer, we suggest that you write a request through this form on our website.